anilox cleaning machine

Narrow-web multiple anilox cleaning machine

Multiple rollers are cleaned at the same time. The automatic cleaning procedure is: · liquid to soften the dry ink or coating medium remaining in the cell - high pressure water cleaning - drying the anilox surface. · After the program is set, one key operation will automatically restore the cell volume Suitable for all types of inks and coating media. · The machine cabinet is made by stainless steel, with good corrosion resistance. · It is widely used for batch cleaning of narrow and small anilox rollers such as label printing, safe and efficient

Anilox roller/sleeve cleaning machine

· The machine is specially designed for roller/sleeve. The cleaning procedure is the same as that of "narrow web cleaning machine". · For cleaning the anilox sleeve, independent tooling prevents the cleaning liquid from penetrating into the sleeve inside. · Automatic cleaning module, one key cleaning, safe, reliable and efficient, no damage to restore cell volume, suitable for all types of ink and coating media · The cleaning caninet is made by stainless steel, with good corrosion resistance. · Widely used in flexographic printing, coating and other industries

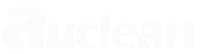

Inline cleaning machine

· Customized guide rail quick installation , using lowpressure eject granular soda powder impact cell to achieve deep cleaning of cell and recovery of ink transfer. · The soda powder has low hardness, does not damage the cell, and is environmentally friendly and recyclable. · During the cleaning process, the powder is automatically recovered and cleaned to realize the in-line cleaning requirements of large anilox roller without disassembly. · It is suitable for inline cleaning of anilox roller in corrugated printing machine, large-scale printing and coating equipment, saving time & labor, safety and reliability.

Ink parts cleaning machine

Ink parts cleaning machine

· The combination of multiple cleaning methods realizes multifunctional cleaning of printing components, and realizes multipurpose of one machine. · The anilox roller adopts the combined cleaning method of spraying cleaning liquid and high-pressure water to effectively prevent the damage of the anilox roller and quickly restore the cell volume of the anilox roller. · Ultrasonic cleaning and high-pressure water cleaning are adopted for parts cleaning to effectively and quickly clean various residues on the surface of parts. Please inquire for details.

Cleaning liquid

Cleaning liquid

It can meet the daily or periodic cleaning of anilox roller, printing plate, rubber roller, inking system, etc., and has the characteristics of safety, environmental protection and high efficiency. It can clean water-based ink, solvent based ink, UV ink, varnish and coating materials. A variety of cleaning liquids can be selected for different cleaning requirements.

Periodic Deep Cleaning liquid

RC-2000

AC-2000(RC-2000) is used for periodic and general deep cleaning of anilox roller. Can solve daily cleaning, can not solve cell clogging

COBRA

COBRA is used for server cell clogging.

Auto Scrubber

Auto Scrubber

Connect the compressed air with the pressure below 0.7mpa/7bar, press the switch by hand and push the brush to clean the roller surface automatically by reciprocating vibration. Compared with manual hand - held brushing method, the work intensity is reduced and the cleaning efficiency is greatly improved

Ultra fine steel/brass brush

Ultra fine steel brush

It is made of ultra-fine stainless steel straight wire and has good resilience. It is suitable for daily manual hand -held cleaning of ceramic anilox roller. Ultra fine stainless steel wire is easy to take out ink residue and does not damage the cell.

Ultra fine brass brush

The brass wire brush is made of good straight elastic brass wire, which is suitable for daily manual hand-held cleaning of metal anilox roller and gravure plate roller. Ultra fine copper wire is easy to bring out ink residue and does not damage the cell.

Anilox cleaning service

Anilox cleaning service

We provide customers with professional anilox cleaning and maintenance services . For the surface condition and the comparison before and after cleaning, provide microscope photography records and analysis. This professional service will be recorded in detail in the anilox roller cleaning and maintenance report, which will help you realize the status management of anilox.

PRODUCTS

SERVICE

CONTACT US