Chamber Doctor Blade System

Chamber Doctor Blade System

Chamber Doctor Blade System is applicable to equipments that use anilox to transfer ink or paint such as flexographic printing machine, corrugated printing machine, varnishing machine, coating machine, etc. We can upgrade and transform the existing rubber roller scraping system into a Chamber Doctor Blade system and the original Chamber system. At the same time, we provide OEM supporting solutions and services for printing, coating and varnishing equipment manufacturers.

The flexo gravure ink transfer unit

The flexo gravure ink transfer unit

The flexo gravure ink transfer unit is suitable for flexo printing, gravure printing, coating ink transfer system. Its features: intelligent and friendly interface, convenient operation, automatic control of viscosity and PH value of ink coating, stable output of ink transfer coating process, improvement of product quality and saving of ink or coating material.

coating unit

coating unit

The coating unit is used in the industries of lithium membrane precision coating, optical film precision coating, offset printing precision varnishing, etc. Its advantages and characteristics are as follows: the CFD simulation aided design of the internal flow channel; Nano anti sticking coating for cavity; Anodic hard oxidation treatment on the whole surface; Design of the best fitting angle of the blade; Blade online fine adjustment compensation mechanism; Multi position adjustment freedom; The blade can be equipped with quick mounting structure design; Integrated quick mounting stainless steel pipe.

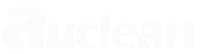

The multi-functional coating proofer

The multi-functional coating proofer

TCoatar300 proofer is mainly used for process test or small batch production equipment before large-scale production such as various coating and lamination. Its main functions are as follows: • determine the parameters of anilox roll (i.e. coating volume) through the analysis of coating layer after coating. • According to the functional requirements of different products, select the best coating glue formula through coating test. • Test the bonding force of various materials to glue and other relevant tests

Varnishment unit retrofit

Varnishment unit retrofit

The retrofit of varnishing system is specially designed for the existing rubber roller varnishing system. It is suitable for the transformation of Heidelberg, Roland, Komori and other equipment. It can be used as an offline varnishing unit or an off-line varnishing unit. Compared with the traditional varnishing mode, the use of chamner doctor blade system to transfer the varnish can well control and improve the uniformity and stability of the varnishing, without increasing the investment of the whole machine, and achieve the effect of low investment and high return. The system can be equipped with paper and varnish or ink drying equipment (for details, please feel free to inquire).

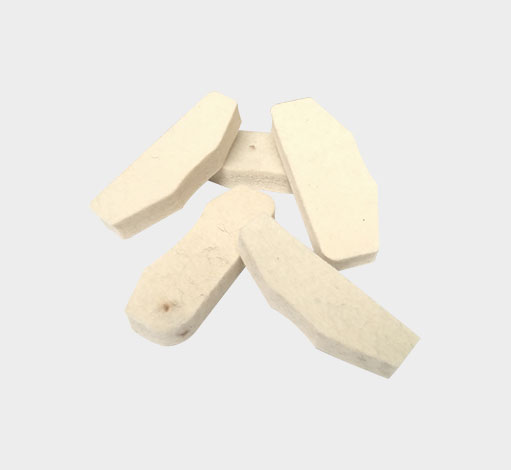

The end seal

The end seal

provides a good ink sealing effect for the chamber doctor blade system, improves the ink transfer quality and saves ink. The end seal is customized according to the size of the chamber doctor blade system and different working conditions of the customer, so as to minimize the pressure of the doctor blade and increase the service life of the doctor blade and the sealing effect. This product is suitable for all kinds of chamber doctor blade systems

PRODUCTS

SERVICE

CONTACT US