- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

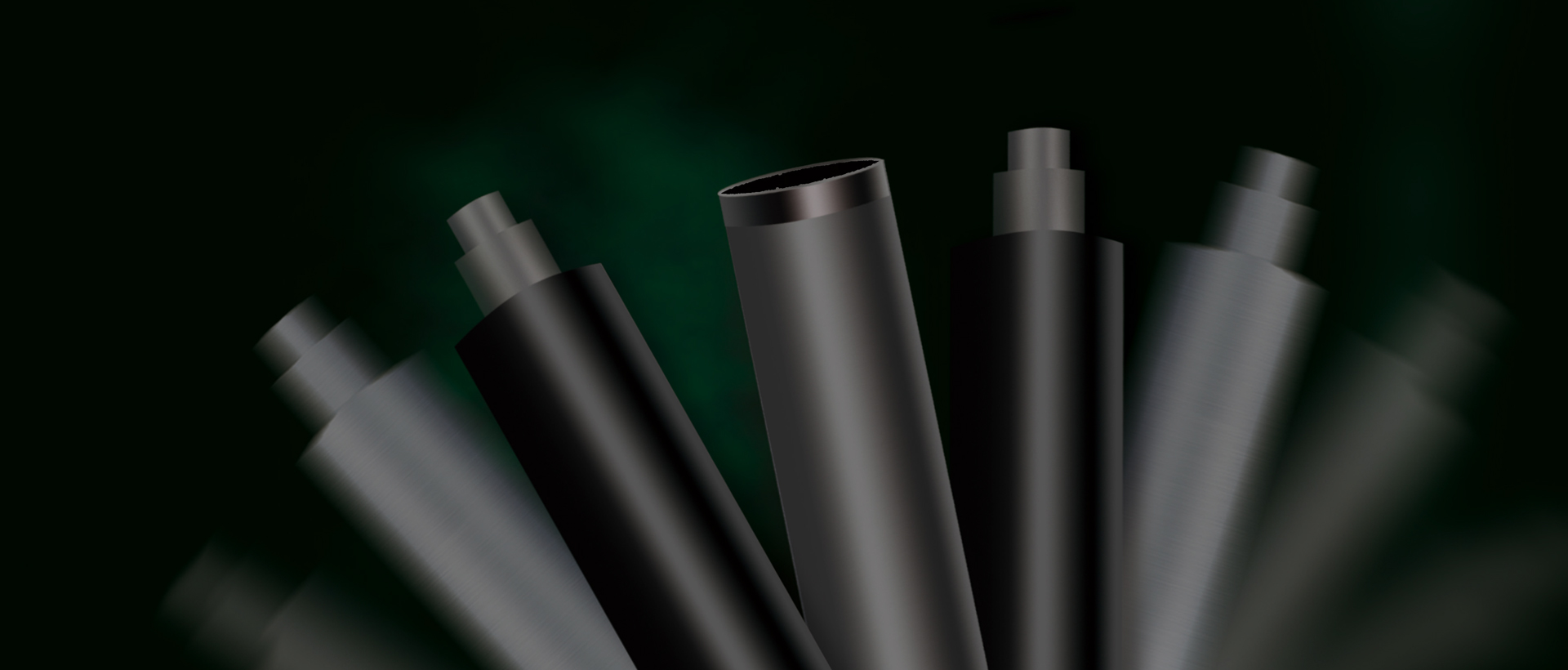

Inking System

Common problems in printing and coating enterprises include deformation of the scraper cavity, poor ink scraping effect, ink leakage, ink splashing, generation of bubbles during operation, changes in ink viscosity, and long cleaning time. Auclean’s Inking System is designed for enterprise working conditions, using high-quality chamber design and combined with fluid mechanics software analysis to optimize performance release. At the same time, the system cooperates with multiple controls of pH value, temperature, and viscosity to help achieve precise transfer effects. This system helps solve technical challenges faced by enterprises, optimize printing processes, and improve product quality and production efficiency.