- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

-

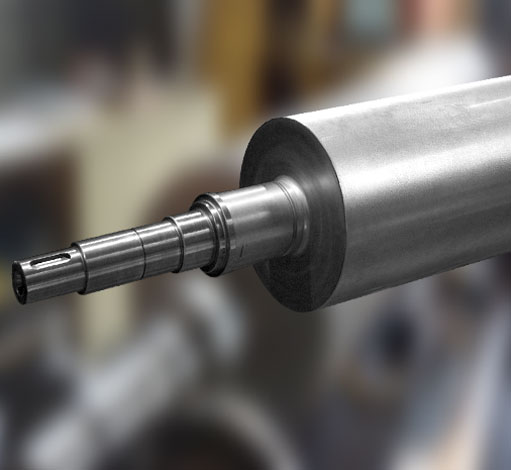

Customized rollersThe commonly used materials for customized rollers include carbon steel, stainless steel, and aluminum alloy. These roller bodies are widely used in equipment in industries such as papermaking, printing and dyeing, printing and packaging, textiles, precision coating, and plastic processing.View More

Customized rollersThe commonly used materials for customized rollers include carbon steel, stainless steel, and aluminum alloy. These roller bodies are widely used in equipment in industries such as papermaking, printing and dyeing, printing and packaging, textiles, precision coating, and plastic processing.View More -

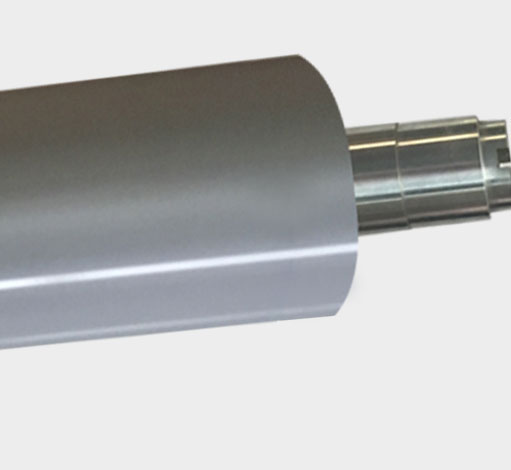

Surface coatingOn the roller surface, metal oxide ceramics or metal coatings are prepared on the roller surface using hot melt coating technology to adapt to different working conditions. The available surface coating materials include: chromium oxide, aluminum oxide, titanium oxide, nickel chromium alloy, tungsten carbide, copper, and stainless steel.View More

Surface coatingOn the roller surface, metal oxide ceramics or metal coatings are prepared on the roller surface using hot melt coating technology to adapt to different working conditions. The available surface coating materials include: chromium oxide, aluminum oxide, titanium oxide, nickel chromium alloy, tungsten carbide, copper, and stainless steel.View More -

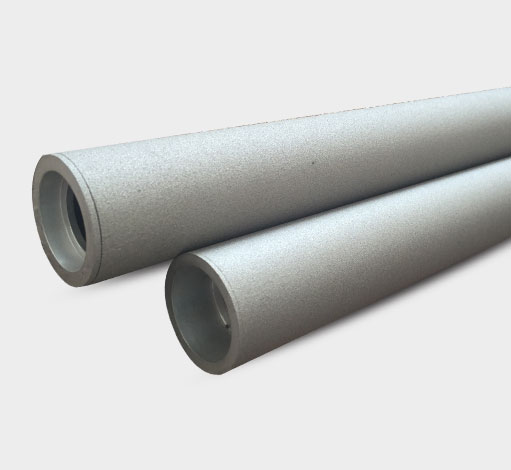

Anti sticking rollerThe anti sticking roller uses hot melt coating technology to prepare non stick high-strength alloy on the surface of the roller body. This treatment makes the roller body have good wear resistance and longer service life to hot melt adhesive, while also having excellent anti sticking performance. It is widely used on transmission rollers in printing and packaging machinery, hygiene product coating machines, printing and dyeing machines, and tape production machines.View More

Anti sticking rollerThe anti sticking roller uses hot melt coating technology to prepare non stick high-strength alloy on the surface of the roller body. This treatment makes the roller body have good wear resistance and longer service life to hot melt adhesive, while also having excellent anti sticking performance. It is widely used on transmission rollers in printing and packaging machinery, hygiene product coating machines, printing and dyeing machines, and tape production machines.View More -

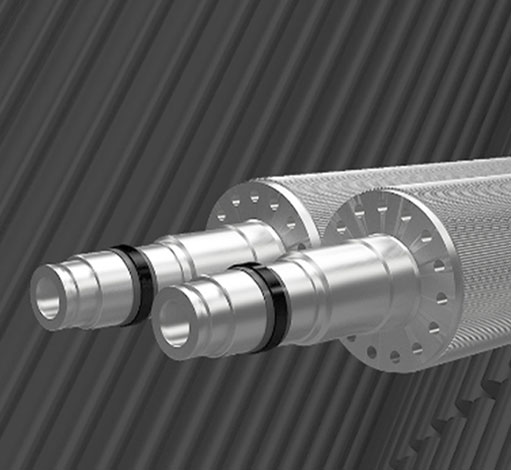

Corrugated rollerCorrugated rollers are the core components of corrugated production lines, and their wear resistance and service life are the main technical indicators for measuring their quality and economy. Excellent performance of corrugated rollers is crucial for the operation of corrugated machines. Precision grinding of irregular corrugated rollers requires very strict tolerances to ensure groove quality. The extensive use of recycled OCC (old corrugated cardboard) in corrugated paper media can exacerbate roller wear. Therefore, coating solutions with high wear resistance and smooth spray surfaces have become the key to achieving high performance and low overall application costs.View More

Corrugated rollerCorrugated rollers are the core components of corrugated production lines, and their wear resistance and service life are the main technical indicators for measuring their quality and economy. Excellent performance of corrugated rollers is crucial for the operation of corrugated machines. Precision grinding of irregular corrugated rollers requires very strict tolerances to ensure groove quality. The extensive use of recycled OCC (old corrugated cardboard) in corrugated paper media can exacerbate roller wear. Therefore, coating solutions with high wear resistance and smooth spray surfaces have become the key to achieving high performance and low overall application costs.View More -

Rubber rollerRubber rollers, as an indispensable key component in the industrial field, are widely used in various machinery and equipment, such as conveyor belts, laminating machines, coating machines, etc. Their design and manufacturing combine various basic and functional materials, aiming to meet the strict requirements for durability, adaptability, and performance in different industrial applications. Roller core material The base roll of the rubber roller, namely the base roll, is the foundation of its structure. Common base roll materials include: Carbon steel: With its excellent strength and cost-effectiveness, it is suitable for standard applications. Carbon fiber: lightweight and high-strength, suitable for applications that require reducing equipment burden and improving speed. Stainless steel: Provides excellent corrosion resistance and is suitable for chemical or humid environments. Aluminum alloy: lightweight and easy to process, suitable for occasions with special requirements for quality and flexibility. Adhesive material The surface material of the rubber roller determines its compatibility, wear resistance, temperature resistance, and specific functional characteristics with the processed material. Common encapsulation materials include: Natural rubber: It has good elasticity and wear resistance, and is widely used in conveying and processing under general conditions. Solid/liquid silicone: Excellent high temperature resistance and chemical stability, suitable for the medical…View More

Rubber rollerRubber rollers, as an indispensable key component in the industrial field, are widely used in various machinery and equipment, such as conveyor belts, laminating machines, coating machines, etc. Their design and manufacturing combine various basic and functional materials, aiming to meet the strict requirements for durability, adaptability, and performance in different industrial applications. Roller core material The base roll of the rubber roller, namely the base roll, is the foundation of its structure. Common base roll materials include: Carbon steel: With its excellent strength and cost-effectiveness, it is suitable for standard applications. Carbon fiber: lightweight and high-strength, suitable for applications that require reducing equipment burden and improving speed. Stainless steel: Provides excellent corrosion resistance and is suitable for chemical or humid environments. Aluminum alloy: lightweight and easy to process, suitable for occasions with special requirements for quality and flexibility. Adhesive material The surface material of the rubber roller determines its compatibility, wear resistance, temperature resistance, and specific functional characteristics with the processed material. Common encapsulation materials include: Natural rubber: It has good elasticity and wear resistance, and is widely used in conveying and processing under general conditions. Solid/liquid silicone: Excellent high temperature resistance and chemical stability, suitable for the medical…View More