- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

-

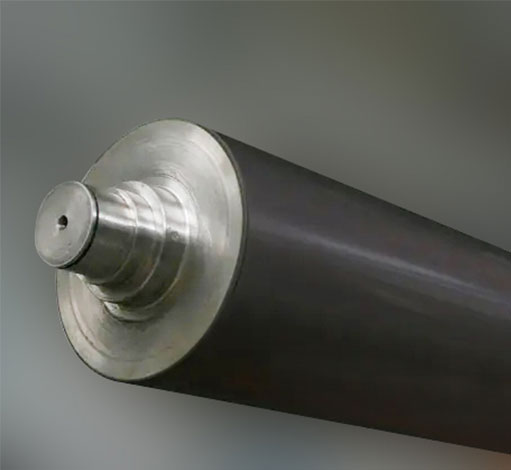

For FlexoWith over 20 years of experience in R&D, manufacturing, and service, we have provided high-quality laser-engraved ceramic anilox rollers to various industries. Using good equipment and stringent production processes, we ensure that the ceramic coating on the rollers features low porosity and high wear resistance. Multi-beam, high-precision laser engraving ensures smooth and uniform cell structures, increased ink release, and easy cell cleaning. Technical Specifications: • Diameter Range: 20–500 mm; • Maximum Length: 5500 mm; • Line Count: 60–1500 LPI; • Cell Shapes: Hexagonal, square, slanted lines, and custom cell designs based on client requirements. Product Advantages: • Cell structure enhances ink transfer efficiency; • Smooth cell walls facilitate easy cleaning; • Low-porosity ceramic coating improves the integrity of high-line-count cells; • Offers wear resistance and corrosion resistance; • Long service life helps reduce costs. Additionally, we provide cell volume inspection reports to ensure precise ink-carrying capacity.View More

For FlexoWith over 20 years of experience in R&D, manufacturing, and service, we have provided high-quality laser-engraved ceramic anilox rollers to various industries. Using good equipment and stringent production processes, we ensure that the ceramic coating on the rollers features low porosity and high wear resistance. Multi-beam, high-precision laser engraving ensures smooth and uniform cell structures, increased ink release, and easy cell cleaning. Technical Specifications: • Diameter Range: 20–500 mm; • Maximum Length: 5500 mm; • Line Count: 60–1500 LPI; • Cell Shapes: Hexagonal, square, slanted lines, and custom cell designs based on client requirements. Product Advantages: • Cell structure enhances ink transfer efficiency; • Smooth cell walls facilitate easy cleaning; • Low-porosity ceramic coating improves the integrity of high-line-count cells; • Offers wear resistance and corrosion resistance; • Long service life helps reduce costs. Additionally, we provide cell volume inspection reports to ensure precise ink-carrying capacity.View More -

For Varnishing• The laser-engraved ceramic anilox rollers are specifically designed for coating units and have been widely applied in coating units of Heidelberg, Roland, Komori, and other offset printing systems, demonstrating excellent performance in water-based and UV varnish coating applications. • Custom solutions are available for equipment manufacturers (OEM), providing comprehensive coating unit integration. • Transitioning from traditional rubber rollers to anilox rollers for coating improves equipment coating performance. Customization Features: With high-precision laser engraving technology, we accurately control cell volume to accommodate various varnish viscosities. Comprehensive testing ensures uniform coating results and optimized ink volume control. Committed to innovation, tailored services, and extensive experience, we aim to meet your needs, helping enhance market competitiveness and operational profitability.View More

For Varnishing• The laser-engraved ceramic anilox rollers are specifically designed for coating units and have been widely applied in coating units of Heidelberg, Roland, Komori, and other offset printing systems, demonstrating excellent performance in water-based and UV varnish coating applications. • Custom solutions are available for equipment manufacturers (OEM), providing comprehensive coating unit integration. • Transitioning from traditional rubber rollers to anilox rollers for coating improves equipment coating performance. Customization Features: With high-precision laser engraving technology, we accurately control cell volume to accommodate various varnish viscosities. Comprehensive testing ensures uniform coating results and optimized ink volume control. Committed to innovation, tailored services, and extensive experience, we aim to meet your needs, helping enhance market competitiveness and operational profitability.View More -

Glue rollIn the packaging and printing industry, particularly for lamination and veneering machines, we provide high-quality ceramic and chrome-plated anilox rollers designed to meet strict requirements for precision and durability. Our high anilox roller technology supports precise glue application, helping maintain product quality and production efficiency. Technical Specifications and Features: • Diameter Range: 20–500 mm; • Maximum Length: 5500 mm; • Line Count: 60–1500 LPI; • BCM: 0.4–24; • Cell Shapes: Hexagonal, square, pyramid, slanted, and custom shapes. Product Features: • Material Options: Ceramic and chrome-plated surfaces to suit various operating conditions. Ceramic rollers provide corrosion and wear resistance, while chrome rollers offer durability and cost-effectiveness. • Cell Shape Variety: A range of cell shapes supports diverse coating requirements and adhesive characteristics, ensuring quality and uniformity. • Precision Glue Control: Meticulously designed cells enable accurate glue application, achieving consistent coating for film lamination and paper veneering. Applications: Our anilox rollers cater to various packaging and printing needs, including: • Glue lamination; • Veneering machines; • Specialized packaging material production. Why Choose Our Anilox Rollers? • Advanced Technology: Manufactured using industry-standard processes to ensure high precision and stable performance. • Customization: Cell shapes and sizes can be tailored to specific requirements. •…View More

Glue rollIn the packaging and printing industry, particularly for lamination and veneering machines, we provide high-quality ceramic and chrome-plated anilox rollers designed to meet strict requirements for precision and durability. Our high anilox roller technology supports precise glue application, helping maintain product quality and production efficiency. Technical Specifications and Features: • Diameter Range: 20–500 mm; • Maximum Length: 5500 mm; • Line Count: 60–1500 LPI; • BCM: 0.4–24; • Cell Shapes: Hexagonal, square, pyramid, slanted, and custom shapes. Product Features: • Material Options: Ceramic and chrome-plated surfaces to suit various operating conditions. Ceramic rollers provide corrosion and wear resistance, while chrome rollers offer durability and cost-effectiveness. • Cell Shape Variety: A range of cell shapes supports diverse coating requirements and adhesive characteristics, ensuring quality and uniformity. • Precision Glue Control: Meticulously designed cells enable accurate glue application, achieving consistent coating for film lamination and paper veneering. Applications: Our anilox rollers cater to various packaging and printing needs, including: • Glue lamination; • Veneering machines; • Specialized packaging material production. Why Choose Our Anilox Rollers? • Advanced Technology: Manufactured using industry-standard processes to ensure high precision and stable performance. • Customization: Cell shapes and sizes can be tailored to specific requirements. •…View More -

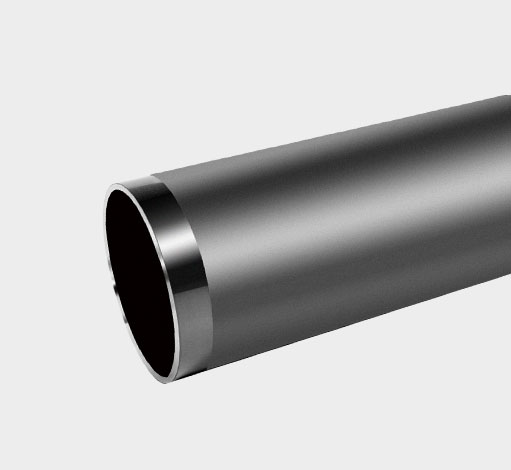

Anilox sleeveThe anilox sleeve adopts an innovative structural design: the inner layer is made of compressible material, the middle layer is made of composite materials such as fiberglass, and the outer layer is covered with aluminum. Ceramic is coated on the surface of the aluminum layer for cell engraving. During installation, by air shaft, the airflow acts on the compressible material, increasing its inner diameter and achieving a tight fit with the air shaft. Once the inflation is stopped, the anilox is firmly fixed on the air shaft. The anilox sleeve, with its innovative design, significantly improves the efficiency of roller replacement and the smoothness of printing production, meeting the current market demand for small batch production and rapid conversion. Shortening preparation time: The design of the anilox sleeve reduces the time for changing plates and adjusting machines, making it suitable for small batch production and shortening the non production preparation time. Material and process innovation: Using specially made composite materials to ensure smooth inner walls of the sleeve and precise cell processing, while meeting the requirements of ink transfer effect. The use of lightweight and durable materials reduces the cost and risk of transportation and handling, and enhances the convenience and safety of operating wide-web flexo printers. Structural optimization: The metal rings at both ends of the sleeve are easy to handle, prevent eccentric deformation,…View More

Anilox sleeveThe anilox sleeve adopts an innovative structural design: the inner layer is made of compressible material, the middle layer is made of composite materials such as fiberglass, and the outer layer is covered with aluminum. Ceramic is coated on the surface of the aluminum layer for cell engraving. During installation, by air shaft, the airflow acts on the compressible material, increasing its inner diameter and achieving a tight fit with the air shaft. Once the inflation is stopped, the anilox is firmly fixed on the air shaft. The anilox sleeve, with its innovative design, significantly improves the efficiency of roller replacement and the smoothness of printing production, meeting the current market demand for small batch production and rapid conversion. Shortening preparation time: The design of the anilox sleeve reduces the time for changing plates and adjusting machines, making it suitable for small batch production and shortening the non production preparation time. Material and process innovation: Using specially made composite materials to ensure smooth inner walls of the sleeve and precise cell processing, while meeting the requirements of ink transfer effect. The use of lightweight and durable materials reduces the cost and risk of transportation and handling, and enhances the convenience and safety of operating wide-web flexo printers. Structural optimization: The metal rings at both ends of the sleeve are easy to handle, prevent eccentric deformation,…View More -

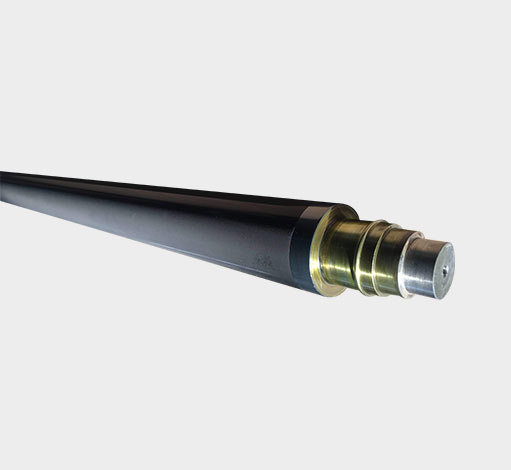

Lightweight aniloxThe base roll is made of carbon fiber composite material, which reduces weight by 50-80% compared to metal. Carbon fiber anilox, with their lightweight characteristics, help improve the production speed of the printing and packaging industry, reduce start stop time, and enhance production efficiency. Meanwhile, its excellent thermal stability and wear resistance help maintain the stability of printing quality, reducing the quality changes caused by thermal expansion and wear of traditional anilox during use. The advantages of carbon fiber anilox in improving printing quality: • High dimensional stability:The low thermal expansion coefficient of carbon fiber and ceramic materials helps the anilox maintain dimensional stability under temperature changes, which facilitates precise alignment and dimensional consistency of printed patterns, making it particularly suitable for long-term printing processes. • Thermal management: Low thermal conductivity reduces heat accumulation duringthe printing process, making the surface temperature of the anilox more uniform, which is beneficial for ink stability, especially in high-speed printing. • Reduce vibration:The high strength and anti vibration properties of carbon fiber help to reduce mechanical vibrations during the printing process, thereby improving printing accuracy and pattern clarity. • Lightweight design: enablesthe anilox to start and stop faster, improving the response speed of the printing machine and suitable for frequent pattern replacement or speed adjustment printing needs. • Strong durability…View More

Lightweight aniloxThe base roll is made of carbon fiber composite material, which reduces weight by 50-80% compared to metal. Carbon fiber anilox, with their lightweight characteristics, help improve the production speed of the printing and packaging industry, reduce start stop time, and enhance production efficiency. Meanwhile, its excellent thermal stability and wear resistance help maintain the stability of printing quality, reducing the quality changes caused by thermal expansion and wear of traditional anilox during use. The advantages of carbon fiber anilox in improving printing quality: • High dimensional stability:The low thermal expansion coefficient of carbon fiber and ceramic materials helps the anilox maintain dimensional stability under temperature changes, which facilitates precise alignment and dimensional consistency of printed patterns, making it particularly suitable for long-term printing processes. • Thermal management: Low thermal conductivity reduces heat accumulation duringthe printing process, making the surface temperature of the anilox more uniform, which is beneficial for ink stability, especially in high-speed printing. • Reduce vibration:The high strength and anti vibration properties of carbon fiber help to reduce mechanical vibrations during the printing process, thereby improving printing accuracy and pattern clarity. • Lightweight design: enablesthe anilox to start and stop faster, improving the response speed of the printing machine and suitable for frequent pattern replacement or speed adjustment printing needs. • Strong durability…View More -

Micro concave coating aniloxMicro concave coating anilox is a high-precision industrial roller specially designed for film coating , such as new energy lithium battery isolation film and solar backsheet coating industry. This anilox adopts advanced materials and manufacturing technology to ensure the precision and efficiency of the coating process, while improving the performance and quality of the final product. The characteristics of the anilox include: High hardness ceramic coating: Using high hardness ceramic materials as coatings not only improves the wear resistance and corrosion resistance of the anilox, but also significantly extends the service life of the anilox. High power laser engraving technology: Using high-power laser fine engraving technology to create cells ensures the uniformity of the shape, size, and distribution of the cells, which is crucial for achieving uniform coating. Ultra precision grinding treatment: The surface of the anilox is subjected to ultra precision grinding treatment to achieve extremely high smoothness, further improving the coating quality and ensuring uniform and smooth distribution of the coating material. 3D scanning microscope measurement: By using a 3D scanning microscope to accurately control the volume, ensuring that the volume of each cell is consistent, precise coating amount control is achieved, and high-precision coating requirements are met. Wide application areas: This anilox is not only suitable for the…View More

Micro concave coating aniloxMicro concave coating anilox is a high-precision industrial roller specially designed for film coating , such as new energy lithium battery isolation film and solar backsheet coating industry. This anilox adopts advanced materials and manufacturing technology to ensure the precision and efficiency of the coating process, while improving the performance and quality of the final product. The characteristics of the anilox include: High hardness ceramic coating: Using high hardness ceramic materials as coatings not only improves the wear resistance and corrosion resistance of the anilox, but also significantly extends the service life of the anilox. High power laser engraving technology: Using high-power laser fine engraving technology to create cells ensures the uniformity of the shape, size, and distribution of the cells, which is crucial for achieving uniform coating. Ultra precision grinding treatment: The surface of the anilox is subjected to ultra precision grinding treatment to achieve extremely high smoothness, further improving the coating quality and ensuring uniform and smooth distribution of the coating material. 3D scanning microscope measurement: By using a 3D scanning microscope to accurately control the volume, ensuring that the volume of each cell is consistent, precise coating amount control is achieved, and high-precision coating requirements are met. Wide application areas: This anilox is not only suitable for the…View More -

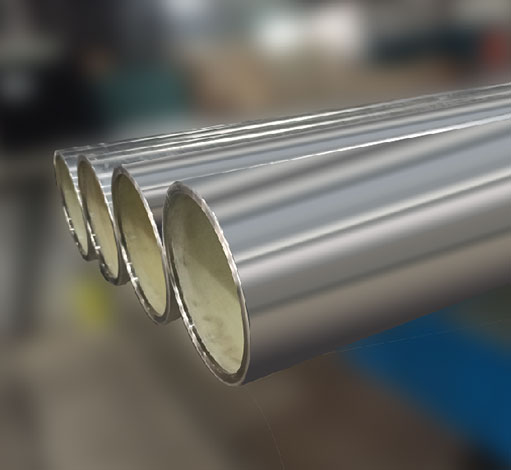

Sleeve anilox baseThe basic structures from the outer layer to the inner liner are: outer aluminum alloy, fiberglass, lining layer, and inner liner made of FibreP material; Alternatively, it could be an outer composite material, a lining layer, or an inner liner made of FibreP material, two different outer materials are available. Both ends of the sleeve are protected by stainless steel rings to enhance the impact resistance.View More

Sleeve anilox baseThe basic structures from the outer layer to the inner liner are: outer aluminum alloy, fiberglass, lining layer, and inner liner made of FibreP material; Alternatively, it could be an outer composite material, a lining layer, or an inner liner made of FibreP material, two different outer materials are available. Both ends of the sleeve are protected by stainless steel rings to enhance the impact resistance.View More -

Anilox optical microscopeHigh definition eyepiece objective lens optical combination, lightweight aluminum alloy structure, built-in LED light source, rechargeable lithium battery, length direction scale resolution 0.005mm/grid, depth direction scale resolution 0.001mm, magnification 200X/400X, optional magnetic base.View More

Anilox optical microscopeHigh definition eyepiece objective lens optical combination, lightweight aluminum alloy structure, built-in LED light source, rechargeable lithium battery, length direction scale resolution 0.005mm/grid, depth direction scale resolution 0.001mm, magnification 200X/400X, optional magnetic base.View More -

Anilox storage trolleySuitable for narrow-web anilox storage and transportation, the "herringbone" wooden bracket has a small footprint and is convenient for safe access.View More

Anilox storage trolleySuitable for narrow-web anilox storage and transportation, the "herringbone" wooden bracket has a small footprint and is convenient for safe access.View More -

Anilox storage and transportation trolley (sTrolley)Mobile storage, vertical storage to avoid deformation of sleeves, anti shake design during transportation safe and reliable, convenient and effortless access to sleeves, large load steel structure, silent and labor-saving double bearing rubber wheels, anti displacement locking casters.View More

Anilox storage and transportation trolley (sTrolley)Mobile storage, vertical storage to avoid deformation of sleeves, anti shake design during transportation safe and reliable, convenient and effortless access to sleeves, large load steel structure, silent and labor-saving double bearing rubber wheels, anti displacement locking casters.View More -

Anilox Roller Protection CoverTo avoid damage caused by roller collision during the movement, and to achieve the protective effect of buffering and collision resistance. It is customized.View More

Anilox Roller Protection CoverTo avoid damage caused by roller collision during the movement, and to achieve the protective effect of buffering and collision resistance. It is customized.View More -

Anilox sleeve protective coverWhen replacing the anilox sleeve, it is easy to damage the surface of the anilox, and collision accidents may also occur during transportation. The protective cover, also known as the protective sleeve, is made of fiberglass composite material and has extremely strong impact resistance, which can effectively avoid accidental damage. The protective cover is customized according to the size provided by the customer.View More

Anilox sleeve protective coverWhen replacing the anilox sleeve, it is easy to damage the surface of the anilox, and collision accidents may also occur during transportation. The protective cover, also known as the protective sleeve, is made of fiberglass composite material and has extremely strong impact resistance, which can effectively avoid accidental damage. The protective cover is customized according to the size provided by the customer.View More