- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

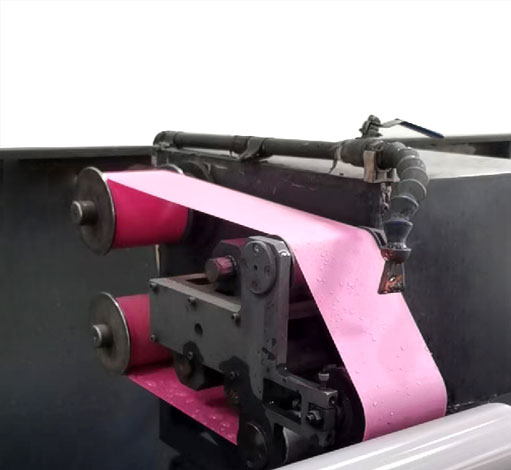

Precision polishing machine

The vibration polishing machine is a revolutionary industrial grade surface treatment tool designed specifically to improve the surface smoothness and machining accuracy of components such as shafts and rollers. It can achieve extremely high surface smoothness with a precision of Ra0.01. This machine plays a crucial role in the processing of shaft parts made of various materials such as metal, plastic, and rubber due to its efficient grinding and polishing capabilities, especially in the manufacturing process of high-precision rollers or shaft parts, demonstrating its irreplaceable value.

Main characteristics

Stainless steel manufacturing: Made of high-quality stainless steel materials, effectively preventing corrosion problems when working in humid or corrosive environments, ensuring long-term stable use of the machine.

German imported accessories: The vibration components and bearings use high-quality German accessories, which ensure the stability and reliability of the machine during long-term operation with high durability, significantly extending the service life of the machine.

Power Drive: Adopting a power drive design, it does not require compressed air supply, saving energy and reducing consumption, while simplifying operation, making the machine more user-friendly.

Easy to operate: Users can operate conveniently and quickly get started without complex training, improving work efficiency and convenience.

Mechanical and electrical stability: The carefully designed mechanical and electrical system ensures long-term stable operation, reduces downtime caused by mechanical failures, and meets continuous production needs.

Easy maintenance: The machine maintenance is simple and easy, and the replacement of vulnerable parts is convenient, ensuring low maintenance costs and efficient production needs.

application

The vibration type precision polishing machine has become an essential tool for manufacturing high-precision shaft and roller components in multiple industries, including aerospace, automotive manufacturing, precision machinery, mold making, and plastic and rubber processing, providing unparalleled surface treatment effects.

Sharing

After years of application feedback and continuous innovation and improvement, this polishing machine has developed into a third-generation product, gaining widespread recognition and praise in the industry, and becoming a benchmark product for high-precision component manufacturing. The development team is willing to share achievements with the industry, promote technological progress and industry development.

In short, the vibration type precision polishing machine, with its excellent performance and innovative design, has become a key tool for improving the quality, efficiency, and reliability of industrial component processing, and is an ideal choice for manufacturers pursuing high-precision machining.