- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

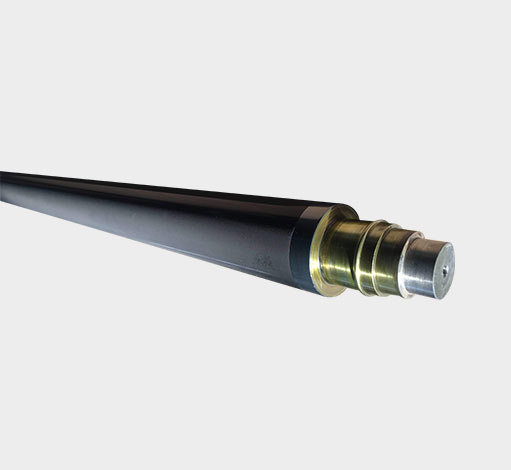

Micro concave coating anilox

Micro concave coating anilox is a high-precision industrial roller specially designed for film coating , such as new energy lithium battery isolation film and solar backsheet coating industry. This anilox adopts advanced materials and manufacturing technology to ensure the precision and efficiency of the coating process, while improving the performance and quality of the final product.

The characteristics of the anilox include:

High hardness ceramic coating: Using high hardness ceramic materials as coatings not only improves the wear resistance and corrosion resistance of the anilox, but also significantly extends the service life of the anilox.

High power laser engraving technology: Using high-power laser fine engraving technology to create cells ensures the uniformity of the shape, size, and distribution of the cells, which is crucial for achieving uniform coating.

Ultra precision grinding treatment: The surface of the anilox is subjected to ultra precision grinding treatment to achieve extremely high smoothness, further improving the coating quality and ensuring uniform and smooth distribution of the coating material.

3D scanning microscope measurement: By using a 3D scanning microscope to accurately control the volume, ensuring that the volume of each cell is consistent, precise coating amount control is achieved, and high-precision coating requirements are met.

Wide application areas: This anilox is not only suitable for the production of new energy fields such as lithium battery isolation films, but also widely used for film coating in multiple fields such as solar panels, precision electronics, and healthcare products, supporting multiple coating materials and processes.

The application of micro concave coating anilox significantly improves the accuracy and efficiency of the coating process, helping manufacturers optimize production processes, reduce costs, and enhance the quality and performance of the final product. Its advanced design and manufacturing technology make it the preferred solution in the high-end coating field.