- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

- Home

- About Us

- Products

- Application

- Service

- News

-

Contact Us

Contact Us

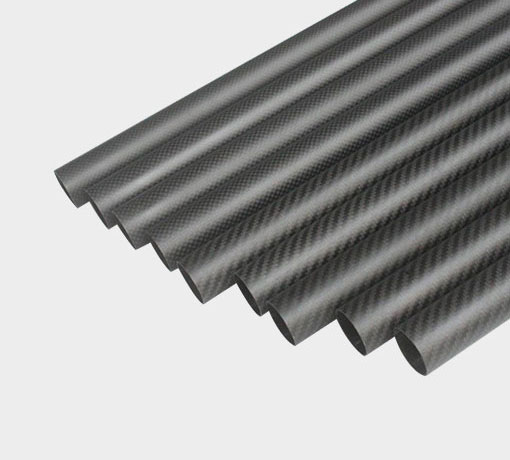

Carbon fiber composite material pipe

Carbon fiber has various excellent properties of elemental carbon, such as light weight, good heat resistance, low coefficient of thermal expansion, high thermal conductivity, excellent corrosion resistance and conductivity. In addition, carbon fiber has fibrous flexibility, making it easy to weave and wrap. Its outstanding advantage lies in its higher specific strength and modulus compared to conventional reinforcing fibers. After composite with resin, its specific strength and modulus are about 5 times that of steel and aluminum alloys. The pipes made of carbon fiber composite materials have been widely used in multiple fields, significantly reducing weight, improving payload, and enhancing performance. They are important structural materials in the aerospace industry.

Advantages:

light weight, low energy consumption, high production efficiency;

Strong strength, strong load-bearing capacity, and diverse functions;

Small creep, high precision, and strong adaptability.

Specification parameters:

Diameter range: 20-800mm;

Maximum length: 8000mm;

Thickness: 1-30mm;

Surface texture: 3K diagonal, 3K plain, UD black, glossy, matte;

Straightness: 0.1mm/m;

Tolerance: ± 0.1mm;

Temperature resistance performance: Normally, the size is stable between minus 50 ℃ and 120 ℃ (special customization can withstand temperatures up to 180 ℃).